Nasze stoły spawalnicze to coś więcej niż sprzęt spawalniczy, to wsparcie, które przekształca Twoją pracę, przenosząc ją na

zupełnie nowy, lepszy poziom. To przemyślana ergonomia, która sprawia, że praca staje się przyjemniejsza i bardziej precyzyjna.

Dzięki dodatkowemu oprzyrządowaniu, spawanie staje się szybsze i bardziej efektywne, co przekłada się na

oszczędności i wzrost zysków.

Jesteśmy świadomi, że spawacze znają się na swoim fachu. Naszą Misją jest

pokazanie im, jak w pełni wykorzystać potencjał stołu spawalniczego i sprawić, by praca stała się jeszcze bardziej

satysfakcjonująca. Wybierz stoły GPPH i zmień swoją spawalniczą rzeczywistość!

Wygoda i precyzja – to dwie główne cechy, które wyróżniają stoły spawalnicze i narzędzia GPPH. Nasz asortyment jest zaprojektowany z myślą o zapewnieniu spawaczom najwyższego komfortu pracy. Dzięki doskonałej konstrukcji i wykonaniu naszych produktów, praca staje się wyjątkowo wygodna, a spawanie osiąga maksymalną precyzję.

Profesjonalna konstrukcja i wykonanie stołów spawalniczych GPPH zapewniają wygodę, na jakiej zależy każdemu spawaczowi. Dzięki ergonomicznym rozwiązaniom i solidnej podstawie, praca staje się bardziej komfortowa, a długie godziny spędzone przy stołach przestają być męczące.

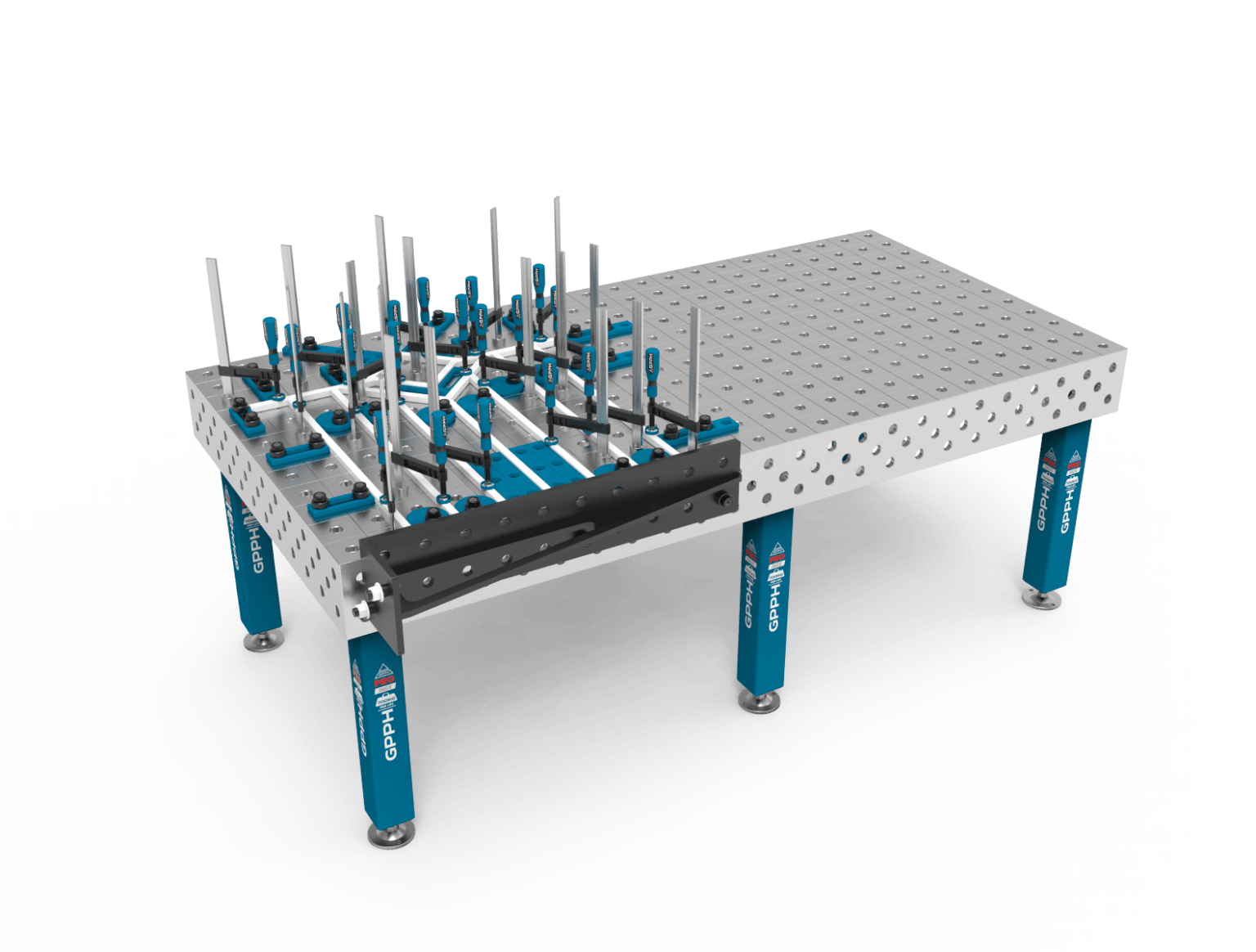

Poszukujesz solidnych stołów spawalniczych o doskonałych parametrach? Oto tradycyjne stoły spawalnicze GPPH! Dostępne są w czterech wersjach: EXPERT, PRO, PLUS i ECO, a każda z nich charakteryzuje się imponującymi nośnościami: EXPERT – 1000 kg na nogę, PRO – 700 kg na nogę, PLUS – 500 kg na nogę i ECO – 250 kg na nogę. Nasze tradycyjne stoły spawalnicze to narzędzia stworzone z myślą o profesjonalistach i hobbystach, którzy cenią jakość i efektywność swojej pracy.

Te niezawodne stoły z solidnymi ścianami bocznymi gwarantują stabilność podczas spawania, zapewniając precyzyjne i bezpieczne wykonywanie prac. Wybierz odpowiedni rozmiar spośród 10 dostępnych, dopasowując go idealnie do swoich potrzeb.

Czy szukasz idealnych stołów spawalniczych do pracy z aluminium i stali nierdzewnej? Nasze nierdzewne stoły spawalnicze w serii PRO INOX i PLUS INOX, wykonane ze stali gatunku 1.4301, to doskonałe rozwiązanie dla Twoich potrzeb. Dzięki ich lepszej przewodności elektrycznej, zapewniają precyzyjne spawanie tych trudniejszych materiałów.

Odkryj stoły spawalnicze INOX i podnieś swoje spawanie na wyższy poziom niezawodności i jakości przy pracach z aluminium i stali nierdzewnej! Wybierz spośród 10 różnych rozmiarów stołów spawalniczych INOX ten, który spełni Twoje wymagania w 100%.

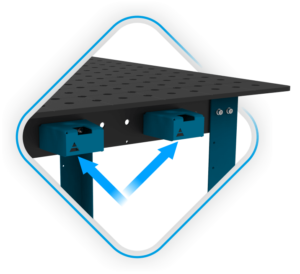

Zaawansowane stoły spawalnicze z hydraulicznym systemem podnoszenia z serii XWT dostępne są w wersjach blatu PRO, PLUS i ECO, a każdy z nich oferuje cztery wersje wymiarowe, co pozwala na idealne dopasowanie do Twoich potrzeb.

Nasza hydrauliczna regulacja wysokości stołu zapewnia nie tylko wygodę, ale także precyzję w dostosowaniu stołu do Twojego spawania. Dzięki temu możesz łatwo dostosować wysokość stołu, aby dopasować go do konkretnej pracy, osiągając optymalne ustawienie dla komfortu i efektywności. To rozwiązanie umożliwia wygodne i bezproblemowe dostosowanie stołu do wysokości i preferencji spawacza. Wypróbuj nasze stoły spawalnicze z hydraulicznym systemem podnoszenia i ciesz się nie tylko wydajnością, ale także pełną kontrolą nad wysokością i ustawieniem stołu podczas swojej pracy.

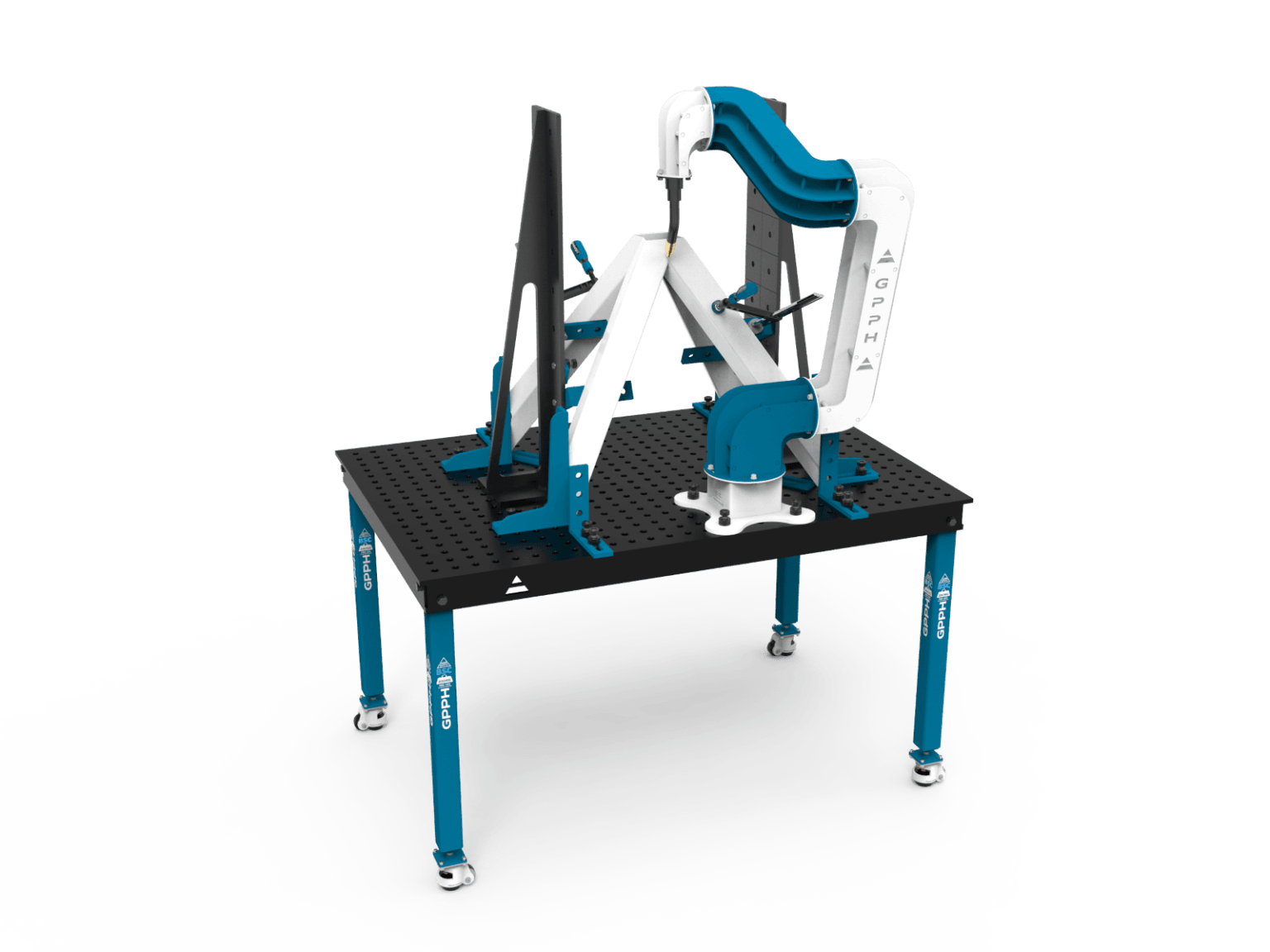

Stół spawalniczo-montażowy BASIC jest idealnym rozwiązaniem zarówno dla profesjonalistów, jak i hobbystów, którzy poszukują niezawodnego narzędzia w przystępnej cenie. Ta seria stołów charakteryzuje się brakiem ścian bocznych. Dzięki szerokiemu wachlarzowi wymiarów i dostępnych akcesoriów, stół spawalniczo-montażowy BASIC może być dostosowany do indywidualnych potrzeb i wymagań użytkownika.

Jednak to nie wszystko! Nasza seria stołów spawalniczo-montażowych BASIC wyróżnia się także jako doskonała baza pod zrobotyzowanestanowiska spawalnicze. Dzięki solidnej i precyzyjnej konstrukcji, stół ten zapewnia stabilność i precyzję potrzebną do zautomatyzowanych procesów spawania. Odkryj jego wszechstronność i wykorzystaj pełen potencjał tego niezastąpionego sprzętu w Twoim warsztacie.

Sprawdź nasz stół spawalniczo-montażowy DIY, zaprojektowany z myślą o różnorodnych potrzebach. Blat o wymiarach 1200x800mm, wytrzymały i precyzyjny, z otworami montażowymi w systemie ⌀16 w siatce 50x50mm oraz grawerowaną podziałką 100x100mm sprawi, że Twoje prace spawalnicze

i montażowe osiągną nowy poziom wydajności i komfortu. Solidne ożebrowanie zagwarantuje trwałość i stabilność.

Ten wielozadaniowy stół sprawdzi się doskonale nie tylko dla spawaczy, ale także majsterkowiczów, stolarzy, mechaników samochodowych i jako stół pomocniczy do maszyn CNC. Zyskaj wsparcie podczas pracy w swoim warsztacie dzięki stołowi spawalniczo-montażowemu GPPH DIY!

Szukasz idealnego stołu spawalniczego, który dostosuje się do Twoich potrzeb? Czy marzysz o narzędziu, które gwarantuje precyzję i wygodę podczas pracy? Oto odpowiedź: modułowe stoły spawalnicze GPPH z serii MWT.

Z ich regulowanym blatem składającym się z frezowanych, przesuwnych płyt o grubości 15 mm, osiągniesz idealne podłoże do swobodnego spawania. Konstrukcja naszych stołów modułowych pozwala zwiększyć liczbę miejsc mocowania narzędzi w szczelinach pomiędzy płytami blatu. Odkryj nowy wymiar profesjonalnego spawalnictwa z naszymi modułowymi stołami spawalniczymi!

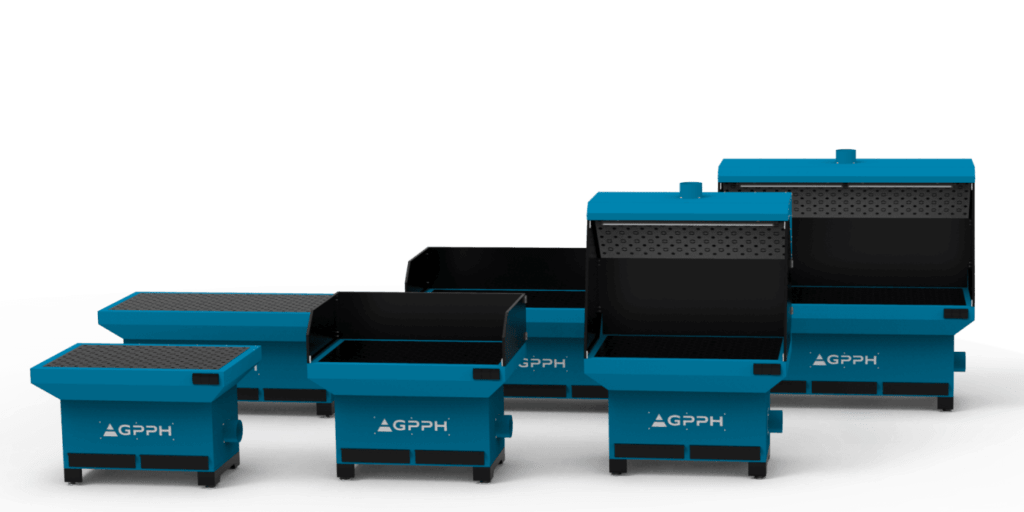

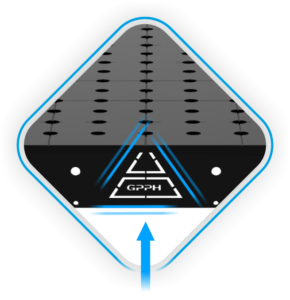

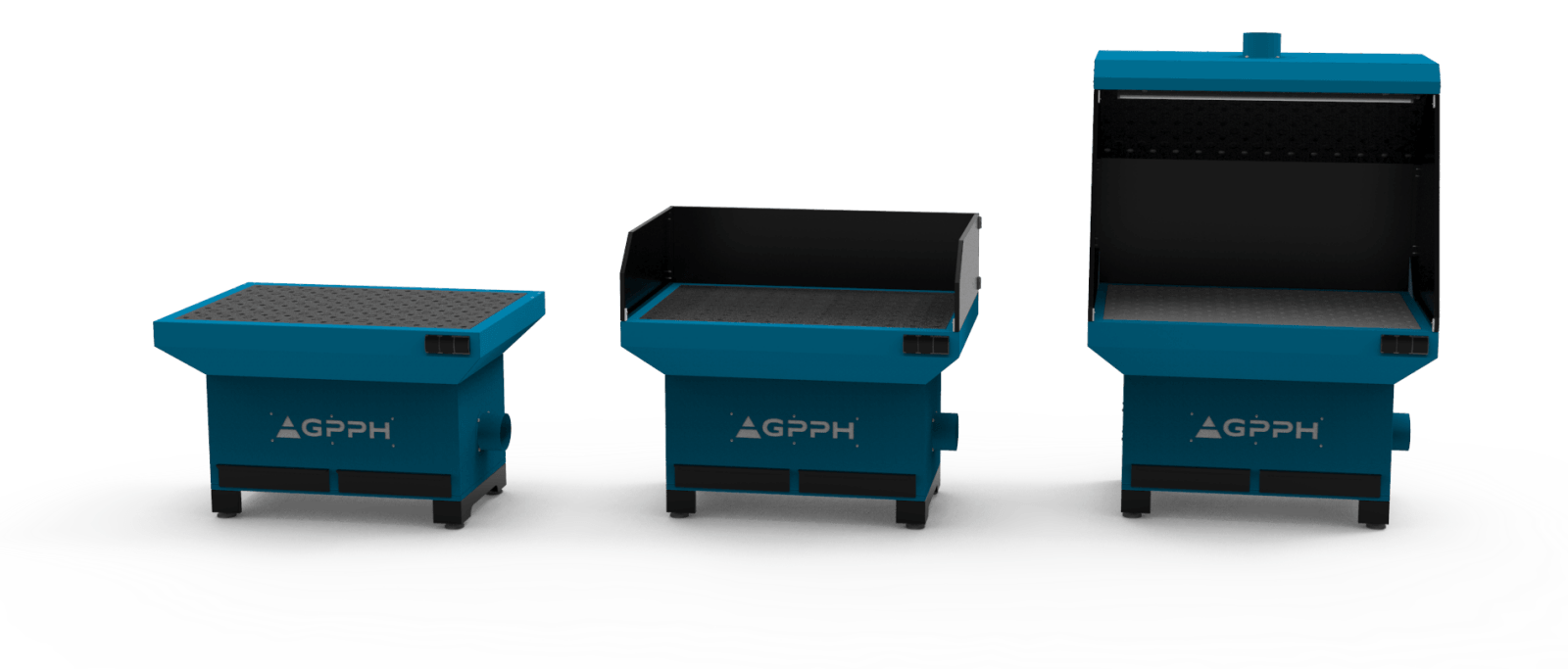

Nasze nowoczesne stanowiska szlifiersko-spawalnicze pozwalają na wychwycenie i usuwanie pyłów i gazów, które powstają podczas szlifowania ręczną szlifierką lub prac spawalniczo-ślusarskich. Współpracują z wentylatorem wyciągowym lub urządzeniem filtrowentylacyjnym, zapewniając wydajne oczyszczenie powietrza.

Dzięki naszym stanowiskom szlifiersko-spawalniczym Twoja praca stanie się bardziej efektywna, a Ty będziesz mógł skupić się na osiągnięciu najlepszych rezultatów. Sprawdź naszą ofertę i wybierz odpowiednie stanowisko dla swoich potrzeb!

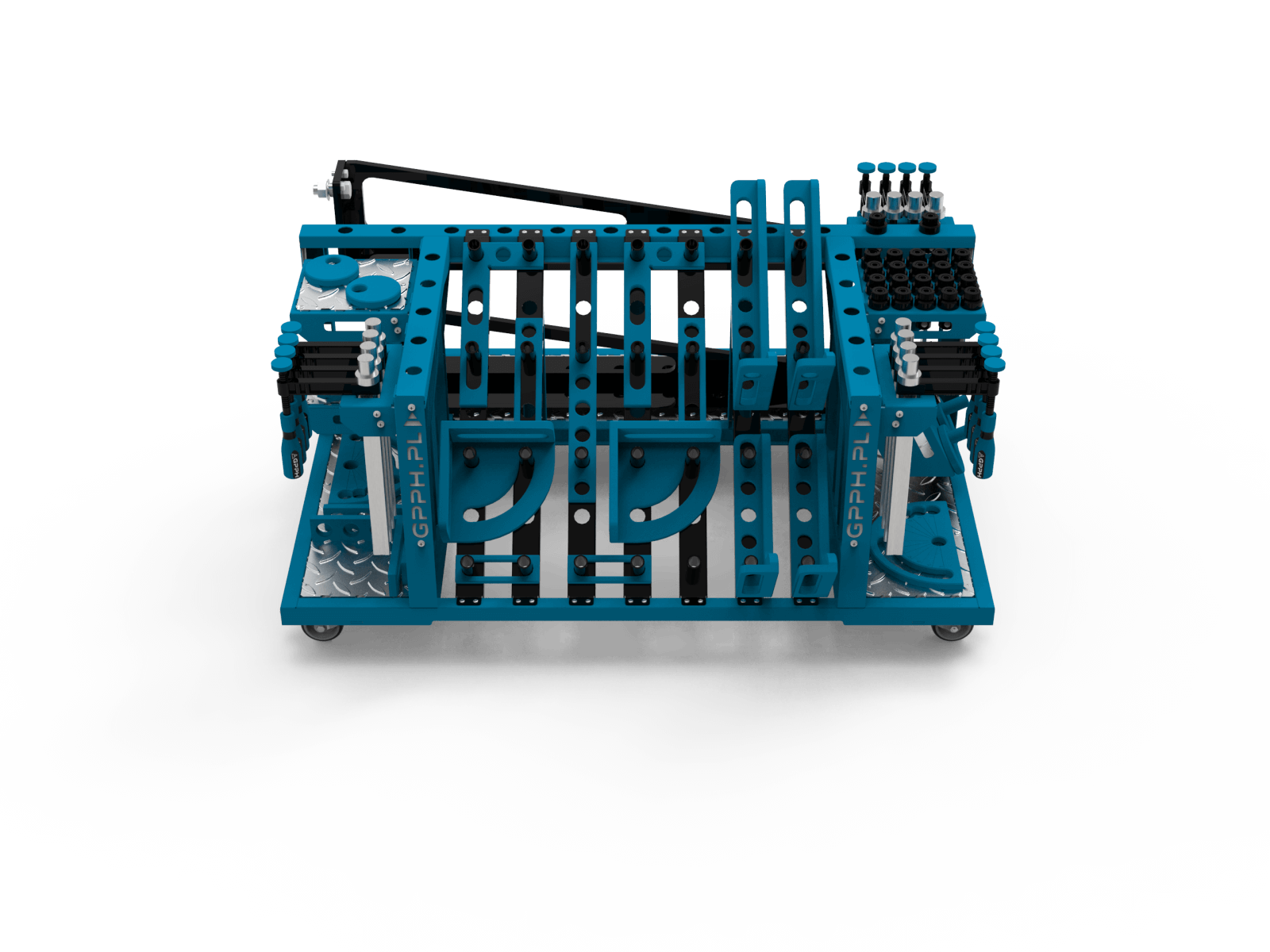

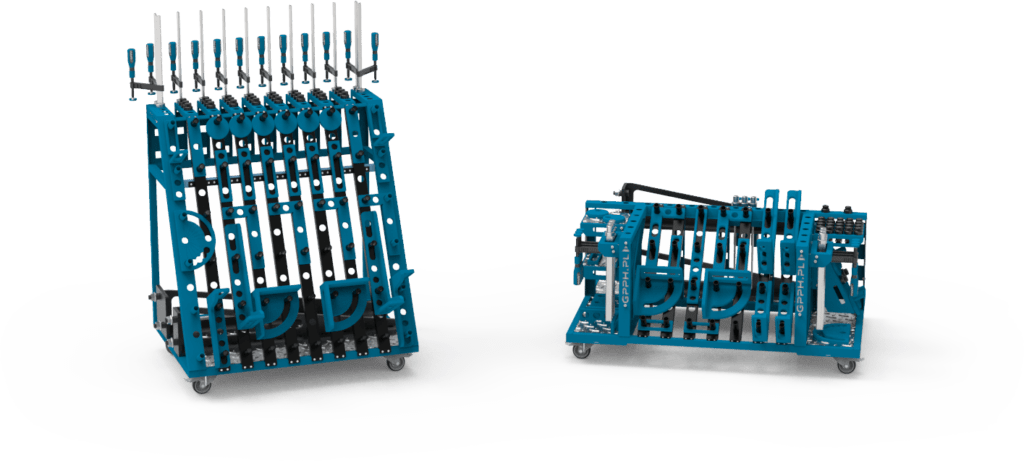

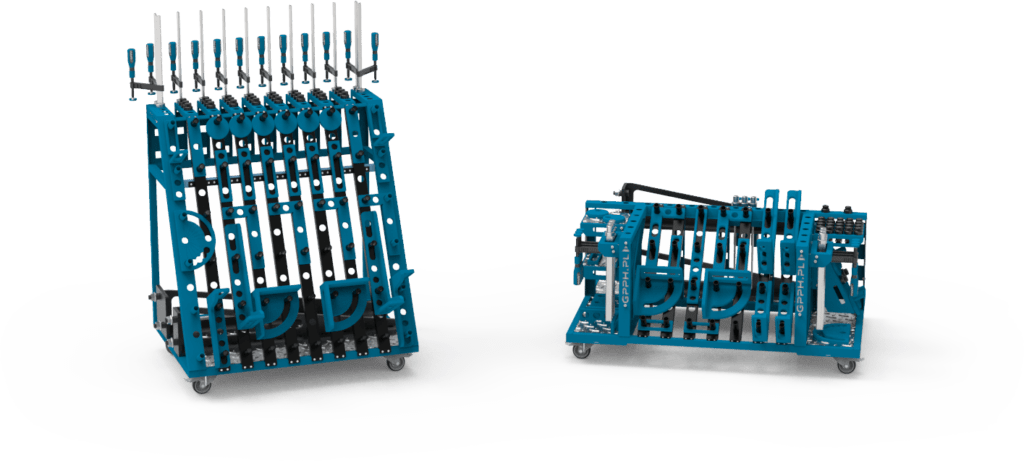

Odkryj naszą bogatą ofertę narzędzi i akcesoriów dedykowanych do stołów spawalniczych. W naszej ofercie znajdziesz szeroką gamę narzędzi do stołów spawalniczych, praktyczne wózki narzędziowe oraz funkcjonalne mobilne półki narzędziowe.

Wierzymy, że wydajna praca wymaga odpowiednich narzędzi, dlatego nasze produkty są zaprojektowane z myślą o zapewnieniu Ci wygody i organizacji w codziennych zadaniach. Niezależnie od tego, czy jesteś profesjonalnym spawaczem czy hobbystą, nasze narzędzia i akcesoria pomogą Ci zrealizować doskonałe projekty.

Szukasz skutecznych rozwiązań do czyszczenia i ochrony stołów spawalniczych? GPPH CHEM oferuje dwa niezwykle efektywne produkty: HD Cleaner – alkaliczny płyn czyszczący oraz Protector – koncentrat antyodpryskowy z inhibitorami korozji. Oba środki są wolne od silikonów i związków olejowych w składzie.

GPPH CHEM to nie tylko produkty, to pewność, że stoły spawalnicze pozostaną w doskonałym stanie, a spawanie stanie się jeszcze prostsze i bardziej satysfakcjonujące dla spawaczy. Postaw na naszą chemię i przekonaj się o jakości naszych rozwiązań!

| Copyright GPPH S.C. © 2024 |

Osiągnij perfekcyjną organizację z naszym małym wózkiem narzędziowym, który pozwoli Ci mieć wszystkie narzędzia w zasięgu ręki.

Potrzebujesz jeszcze większej pojemności? Nasz duży wózek narzędziowy pomieści nawet najbardziej rozbudowane zestawy narzędzi. Wszystko będzie uporządkowane i gotowe do użycia.

Pracuj sprawnie i precyzyjnie przy tworzeniu konstrukcji płaskich i przestrzennych dzięki naszym narzędziom i wyposażeniu do stołów spawalniczych.

Wybierz gotowe zestawy narzędzi lub skomponuj swój zestaw i zyskaj usprawnienie Twojej codziennej pracy.

Pielęgnacja stołu spawalniczego to klucz do jego długiej żywotności. Wybierz profesjonalne środki chemiczne GPPH CHEM i ciesz się efektywną pracą przez wiele lat.

W naszej ofercie znajdziesz specjalne produkty, które zapewnią odpowiednią ochronę i pielęgnację Twojego stołu spawalniczego.

Osiągnij perfekcyjną organizację z naszym małym wózkiem narzędziowym, który pozwoli Ci mieć wszystkie narzędzia w zasięgu ręki.

Potrzebujesz jeszcze większej pojemności? Nasz duży wózek narzędziowy pomieści nawet najbardziej rozbudowane zestawy narzędzi. Wszystko będzie uporządkowane i gotowe do użycia.

Nasze innowacyjne stanowiska szlifiersko-spawalnicze skutecznie eliminują pyły i gazy generowane podczas prac szlifierskich i spawalniczych. Współpracują z wentylatorem wyciągowym lub filtrowentylacyjnym, skutecznie poprawiając jakość powietrza wokół stanowiska.

Dzięki nim osiągniesz większą efektywność w pracy, skupiając się na doskonałych rezultatach.